(30 min)

Introduction to manufacturing plant (15 min)

Empathize phase

Running a Bolt and Nut Manufacturing Process

Present students with a hypothetical situation where they are responsible for managing a smart factory that produces and assembles bolts and nuts.

- The layout example of a manufacturing plant

- The factory is equipped with 5 different machines:

- a lathe for bolt production, production time for one unit is 1 minute

- a pressing machine for nut production, production time for one unit is 2 minutes

- an assembly machine that assembles bolts with nuts, the production time for one unit is 30 seconds

- and AGV for transporting material between machines

- transport from the press machine to the assembly line takes 20 seconds

- transport from the lathe machine to the assembly line takes 30 seconds

- The end goal of production is to make an assembled part containing one bolt and one nut

- The blue arrow shows the material flow of the production process

- The purple dashed arrows show the potential information flow between peers to organize the manufacturing process

Define phase

Present students with problems focusing on the organization of the production process:

- Production Sequence: How can we sequence the production of bolts and nuts to match the assembly rate, ensuring continuous flow without stoppages?

- Balancing Production Output: Given the difference in production times for bolts and nuts, how can we organize the workflow to ensure neither machine is left idle for too long?

- Resource Allocation: How can we allocate and manage resources, such as raw materials and machine time, to ensure optimal production?

- Communication and Coordination: How might we improve the communication between machines or sections of the factory to ensure timely updates and coordination?

- Queue Management: How can we organize the queue at the assembly machine to prevent backlogs and ensure a steady flow of parts to be assembled?

These problems focus on the organizational challenges inherent in the production line scenario. Addressing them will help ensure a smooth, efficient, and coordinated manufacturing process.

Introduction to peer-to-peer communication network topology (15 min)

Empathize phase

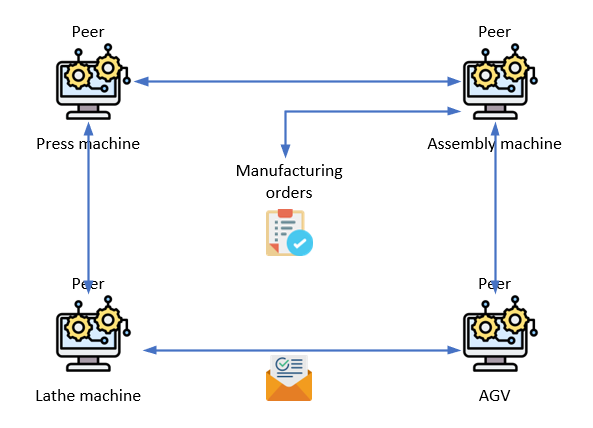

Present students with a peer-to-peer topology that will be used as a communication network for the manufacturing organization

The network consists of peers each corresponding to certain tasks:

- manufacturing order

- this entity only provides requests for bolts and nuts production it does not organize anything

- the role of the manufacturer planer can be distributed among peers making it decentralized

- other manufacturing entities

- each machine represents a peer

- peers communicate with each other to complete their tasks

- Message:

- messages are sent from one peer to another

- each message should contain the source and target destination and some instructions

Define phase

1. Organization of manufacturing process:

- how the process of manufacturing planning can be reorganized in a more decentralized way

2. Peer Autonomy and Responsibility:

- Explore how individual machines (peers) can take on autonomous roles for specific tasks, autonomous job queuing based on priority, and direct negotiation with other machines for resource allocation.

3. Dynamic Job Scheduling:

- Discuss the concept of dynamic and decentralized job scheduling, where tasks are not assigned by a central planner but are instead advertised to the network and claimed by the most suitable machine based on current load, proximity, and availability of resources.

4. Order-Driven Task Allocation:

- Investigate how manufacturing orders can be used to drive task allocation among peers directly. This involves orders being broadcasted to the network, and machines (peers) autonomously deciding to take on tasks based on their current capacity, capabilities, and proximity to required materials.