Introduction to manufacturing plant (15 min)

Running a Bolt and Nut Manufacturing Process

Present students with a hypothetical situation where they are responsible for managing a smart factory that produces and assembles bolts and nuts.

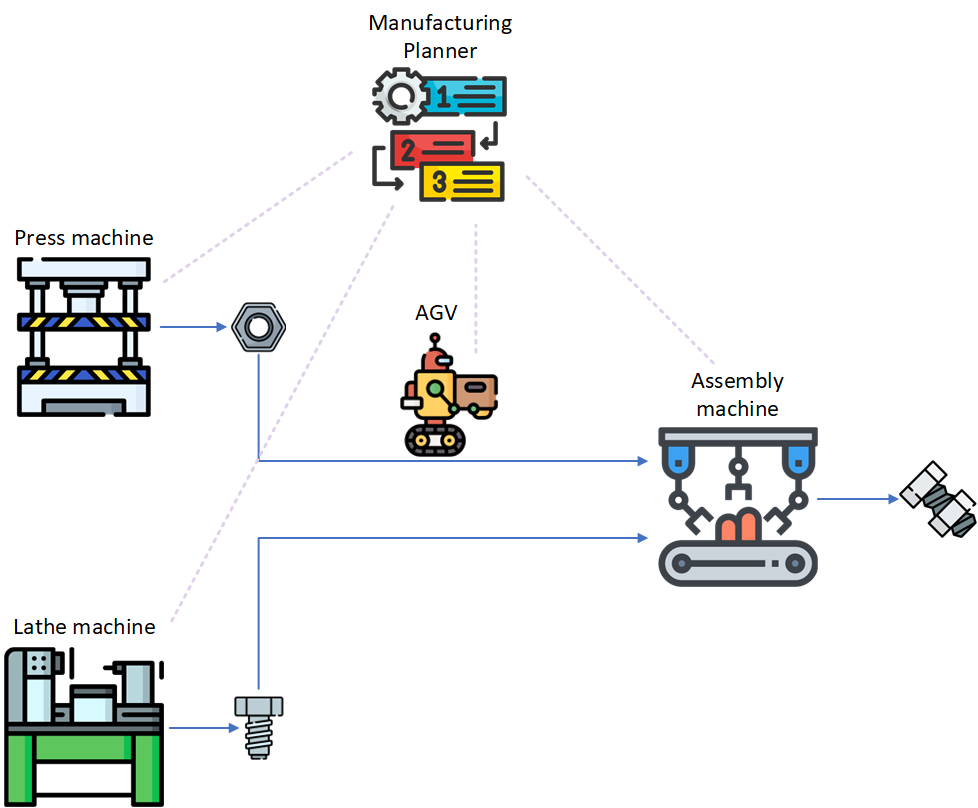

- The layout example of a manufacturing plant

- The factory is equipped with 5 different machines:

- a lathe for bolt production, production time for one unit is 1 minute

- a pressing machine for nut production, production time for one unit is 2 minutes

- an assembly machine that assembles bolts with nuts, the production time for one unit is 30 seconds

- and AGV for transporting material between machines

- transport from the press machine to the assembly line takes 20 seconds

- transport from the lathe machine to the assembly line takes 30 seconds

- The factory also assigns the role of manufacturing planner which is not a physical object but the role is to coordinate and organize the manufacturing process

- The end goal of production is to make an assembled part containing one bolt and one nut

- The blue arrow shows the material flow of the production process

- The purple dashed arrows show the information flow that the production planner has to have to efficiently organise the manufacturing process

Define phase

Present students with problems focusing on the organization of the production process:

- Production Sequence: How can we sequence the production of bolts and nuts to match the assembly rate, ensuring continuous flow without stoppages?

- Transportation Efficiency: How might we organize the AGV's routes to reduce transport times and avoid potential traffic or congestion?

- Balancing Production Output: Given the difference in production times for bolts and nuts, how can we organize the workflow to ensure neither machine is left idle for too long?

- Resource Allocation: How can we allocate and manage resources, such as raw materials and machine time, to ensure optimal production?

- Communication and Coordination: How might we improve the communication between machines or sections of the factory to ensure timely updates and coordination?

- Queue Management: How can we organize the queue at the assembly machine to prevent backlogs and ensure a steady flow of parts to be assembled?

These problems focus on the organizational challenges inherent in the production line scenario. Addressing them will help ensure a smooth, efficient, and coordinated manufacturing process.

Introduction to server-client communication network topology (15 min)

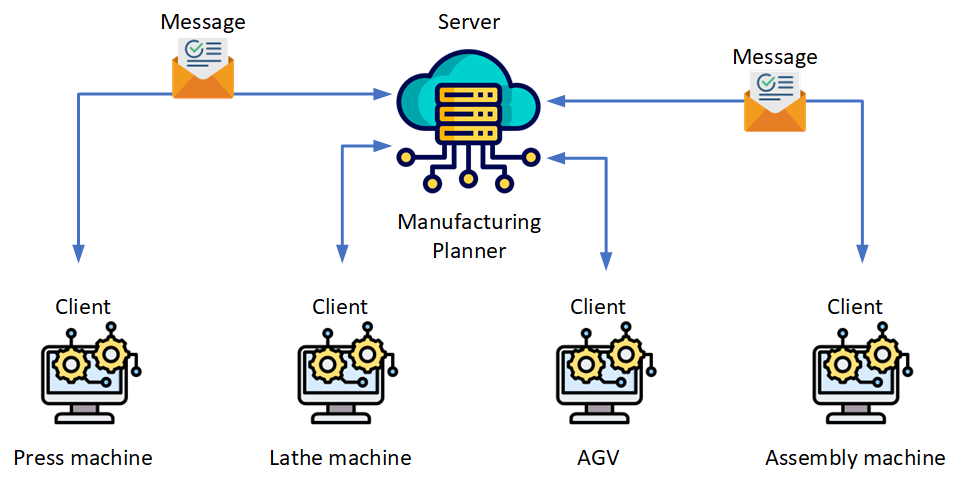

Present students with a server-client topology that will be used as a communication network for the manufacturing organization

- The network consists of one server and 5 clients

- Server:

- includes also the role of the manufacturing planner

- receive messages from clients and react with new messages back to clients to organize the production process

- Client:

- each machine represents a single client

- clients pull messages from server

- Message:

- messages are send from client to server

- server only responds to message from client

- each message should contain the source and target destination and some instructions

Define phase

- Server Overload: How can we ensure the server effectively handles multiple simultaneous messages from clients without getting overwhelmed or causing delays?

- Message Prioritization: How might we prioritize messages to ensure that critical tasks or machine instructions are addressed first?

- Message Integrity: How can we ensure that messages sent between the server and clients are accurate and free from errors or corruption?

- Client Dependency: How might we organize the system such that if one client (machine) goes offline or faces an issue, it doesn’t disrupt the entire production process?

- Message Structuring: How can we standardize the structure of messages to ensure clarity and consistency in communication?

- Client Identification: How can we uniquely identify each client to ensure that messages are sent to and received from the correct machine?